Fundraising Lessons From the Liberty Ship Innovation

Shipbuilding pre-WWII was akin to fundraising before mass market channels existed—highly bespoke and tailored to the buyer, time consuming and with non-scalable labor as the primary input.

Necessity often being the mother of all invention, the shipbuilding industry in the United States underwent a radical transformation to meet the needs of the Allied cause.

But these weren’t military innovations, instead they were commercial. The merchant ships carrying goods to Europe saw escalating demand and increasing disruption to supply with German subs sinking ships full of cargo.

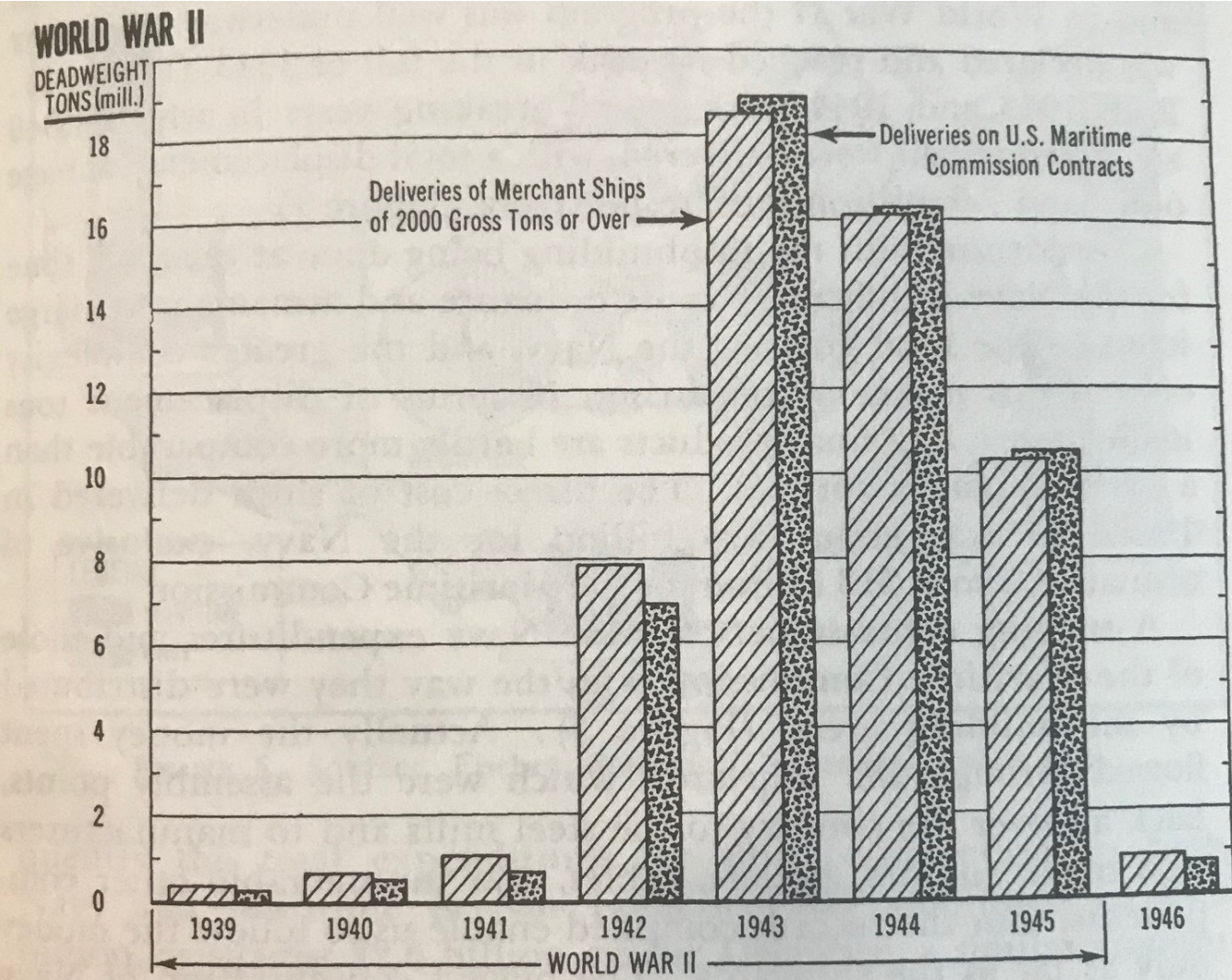

In 1940 the US was contracted to build 60 ships totalling 600,000 tons of merchandise. By 1942 the same industry was producing 9 million tons and a whopping 15 million in 1943.

How was this massive increase in output possible? There are a host of factors, all tied to innovative ways of thinking fueled by a crushing sense of urgency. All the old, traditional, “proven” methods had to be rethought. Not nice to have or as side project or blue-sky initiative but rather, an innovate-or -die mindset.

How was this massive increase in output possible? There are a host of factors, all tied to innovative ways of thinking fueled by a crushing sense of urgency. All the old, traditional, “proven” methods had to be rethought. Not nice to have or as side project or blue-sky initiative but rather, an innovate-or -die mindset.

How many organizations are way too fat and happy or staid with a status quo, good enough mindset? Not an option in the early 1940s.

One of the critical factors to this massive increase in output was a continuous improvement process of user feedback. The Maritime Commission actively solicited employee ideas to speed up the shipbuilding process with comment boxes. What’s more, they incentivized the behavior with money and autonomy.

If an idea was approved the worker received a bonus payment plus was tasked with implementing the idea. By 1945 they had collected more than 3,000 suggestions that collectively saved $45 million and 31 million manhours. Further the suggestions were compiled into books and distributed throughout the shipbuilding industry.

Here are a few examples of user feedback ingenuity from the only source that really knows – frontline staff (read employees and your donors).

- One worker invented a special clamp so a chalk-line could be held by just one employee

- Another created a mock engine room for laying out and fitting the engine room flooring before installing it on the ship, saving thousands of hours of labor.

- Creating posters detailing the different welds to be used throughout the ship

This continuous improvement process reduced the time to produce what were dubbed, Liberty Ships, from over 200 days to under 50.

What’s your continuous improvement process? Do you treat your control and status quo as needing to be disrupted and rethought or else? Or is your control world and journey and segmentation thought of as a mostly comfortable, steady as she goes tanker ship?

Kevin

Kevin, love the comparisons!

So brilliant and useful … I’m at a loss for words.

I’m right now working with a wonderful NGO that’s undertaking a strategic plan. Kevin’s comments in this essay could awaken fresh perspectives for them. Why? This NGO moved away from a SWOT (Strengths, Weaknesses, Opportunities, Threats) planning model to what’s called a SOAR model (Strengths, Opportunities, Aspirations, Results). Why? “Because people tend to get overly focused on the shortcomings with SWOT.”

My unspoken translation of this leader’s comment: “You’re avoiding the hard stuff that matters most to effective planning.” Kevin’s article could be a valuable course correction for them.

Hi Tom, thanks for the feedback and glad to hear the post can be put to such good, direct use. And as an aside, all for anything that puts a death knell to SWOT analysis.